THE ATEX WALLBOX

Unlimited operation of robots in ATEX Zone 1.

Reliable support for

autonomous operation.

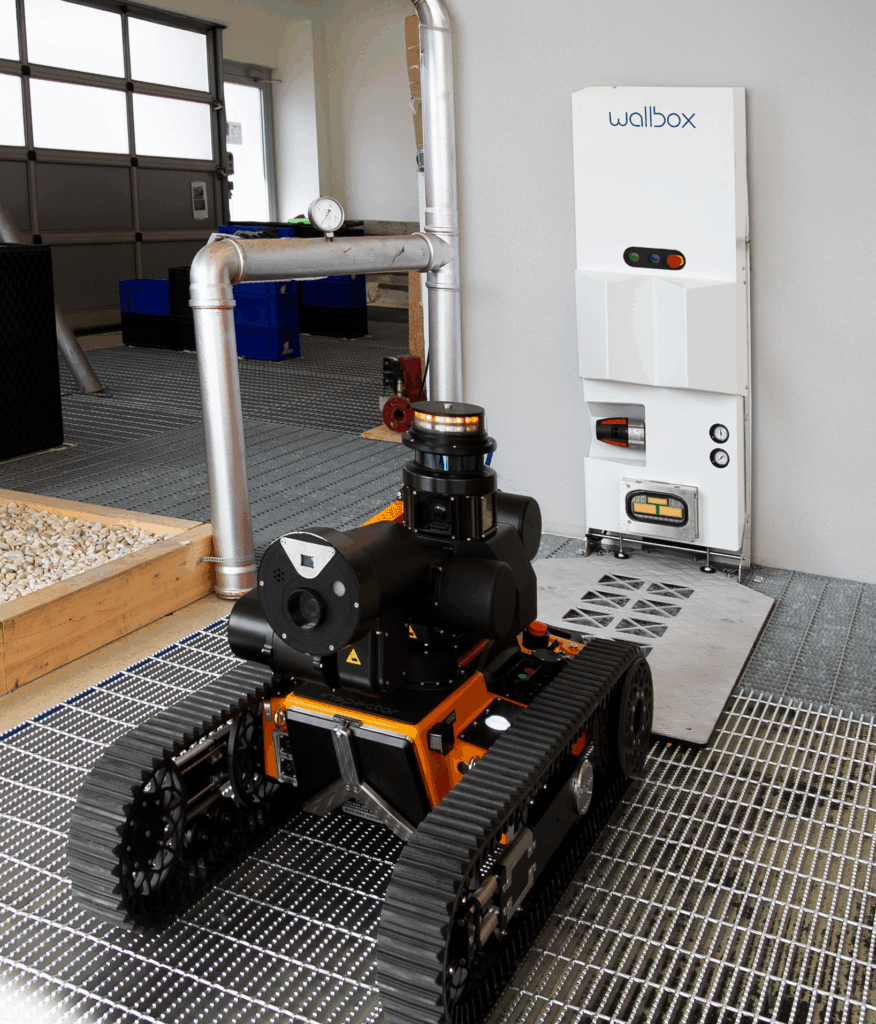

The Taurob Wallbox is a stationary docking

system designed for Taurob robots.

When docked, the robot’s battery is fully

recharged in only 100 minutes and the

robot is automatically pressurized through

external nitrogen supply.

ATEX Zone 1.

Made for the energy sector.

The Taurob Wallbox is certified for ATEX

Zone 1 areas, making it an unrivaled

docking system.

The Taurob Wallbox is certified for ATEX

Zone 1 areas, making it an unrivalled

docking system. In fact, it enables both charging and

pressurization of ATEX-certified robots

directly within ATEX Zone 1 environments.

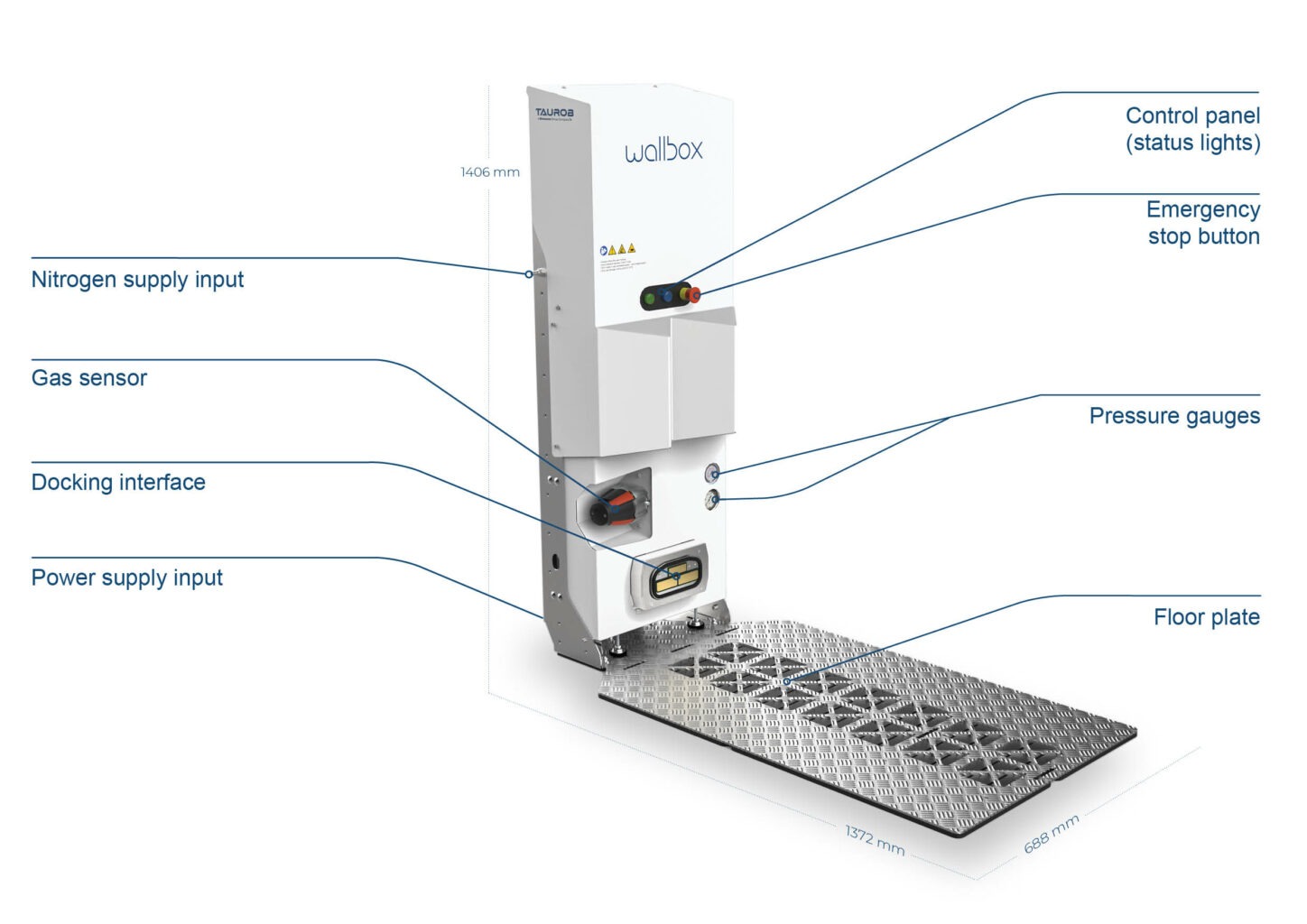

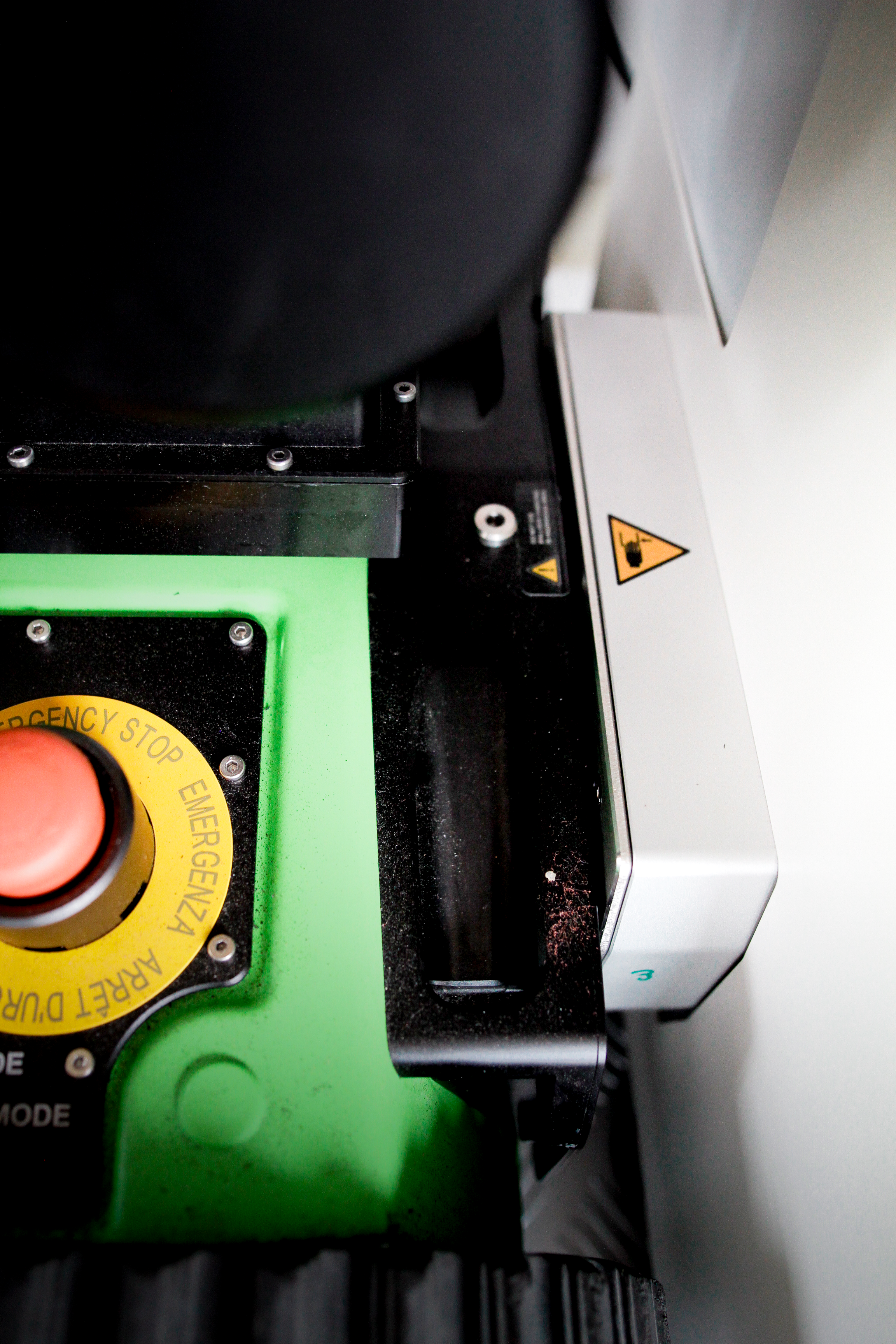

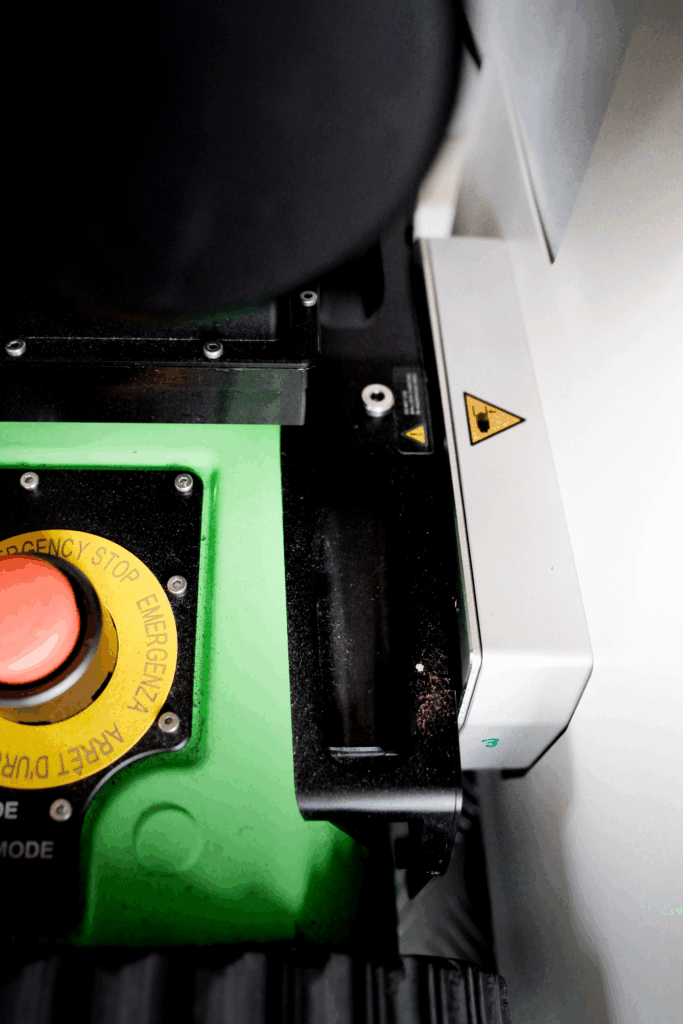

CONTROL PANEL

with status lights and

emergency stop

INTEGRATED GAS SENSOR POLYTRON

for safe charging of the Dräger X-am 8000

INNOVATIVE SEALED DOCKING SYSTEM

for charging and pressurizing

Built for reliability.

The Wallbox has no powered moving parts and requires no internet connection, ensuring robust and continuous operation in industrial environments.

Advanced data integration.

Additionally, the Wallbox features a manual purge function, allowing operators to purge the robot manually after maintenance or repair activities.

BUILT FOR EXTREME WEATHER

FULL ROBOT RECHARGE IN ONLY 90 MIN.

CHARGING IN ATEX ZONE 1

Specifications.

Specs subject to change.